What business leaders should be focusing on heading Q3-Q4 ?

August 11, 2020

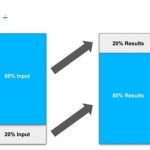

80/20 Rule

August 11, 2020Ways Your Business Can Reduce Packaging Waste

There is a sudden rise in the need for packaging, it’s important to remember what that means for our environment. Because of this, many companies are starting to use more sustainable packaging materials to ensure that the footprint they leave once the packaging becomes waste is minimal.

The following are the different ways in which Companies can help decrease packaging waste. These tips are easy to implement and will help both the company and the environment.

1. Consider the Packaging Materials Used

One of the best ways to decrease packaging waste is to start at the beginning by using reusable or recyclable materials, and you are already on your way to a win.

Get into the specifics of how you are packaging your products and what materials have been used. Make sure that the width of the film you are using is necessary for a proper seal. Sometimes reducing the packaging width by a small amount can not only reduce costs but significantly reduce the amount of waste created during the packaging process.

Also, make use to use the packaging waste you create in the production of the finished goods if possible. If you don’t need the packaging beyond its initial use, recycling is the best option.

The number of items you regularly use around the office or plant that are fully recyclable may surprise you in a big way. Aluminum cans and foil, magazines, and even juice cartons can all be recycled.

2. Encourage Minimal Packaging

The shape and design of your packages is the most significant aspect of material costs. Packages are also a key element in the success of any product. Starting with a package design that incorporates sustainability and recyclability helps the environment.

The more minimalistic the package, the less waste is created, leading to a reduced product cost. Reduced packaging also leads to consuming less energy to manufacture the material and the packaging, which further reduces costs. Additionally, less fuel is used to transport smaller items, saving money there as well.

3. The Right Training is Important

The best way to make the most impact to increase sustainable packaging is to ensure that your entire team is adequately informed, trained and follows the protocols that you’ve set up. After all, people are always the best resource.

Don’t assume that staff is fully aware of the importance of using properly sized boxes, recyclable materials, etc. Communicating with staff is a simple way to get everyone on the same page, working together to increase efficiencies, save costs, and even protect the environment.

Make sure your commitment to reducing waste is clear, and is written down in multiple places (such as on easy-access bulletin boards and perhaps company-wide email), and emphasize the significance of ensuring that your workplace is one that values reducing waste.

The Whole Package: 7 more Ways Companies Can Reduce Packaging Waste

1. Lighten the load

Shipping materials, like wood pallets, can be very heavy and add weight to an already large load. Extra weight equates to more fuel consumption and greater carbon emissions and also attracts extra shipping costs. Reducing packaging weight reduces impact on the environment as well as your wallet. In some cases we’ve swapped out wood pallets for reusable recycled-content plastic containers and have cut waste, weight and also the cost.

2. Use spatial reasoning

Rethink the way items are packed into a box to maximize space.

3. Keep ‘em separated

If packaging materials are mixed, like a cardboard liner with a wood frame, stapling the two pieces together makes recycling inconvenient because the materials must be separated first. If mixed materials must be stapled, allow for “breakaway”: easy separation of the parts.

4. Source responsibly

GM works with a supplier overseas that just provides the wheels for GM vehicles. They are shipped to a warehouse in the states where the wheels are repackaged in recyclable containers, and then sent to a plant. They are working with this supplier to use recyclable material to ship the products directly to the plants. By eliminating the middle warehouse step, you also slash cost and reduce waste.

5. Design before you sign

GM also provides guidelines outlining how to maximize the storage capacity of delivery trucks and the carriers. And because shipping is a significant cost, packing as many parts as possible in one load is key to saving fuel and money. Reviewing packaging plans with suppliers before contracts are signed eliminates many of these problems

6. Make safety a priority

GM need materials to be shipped in boxes with lids similar to shoe boxes so tape isn’t required to seal the item for shipping. When tape is used, an employee will have to use a knife to open the boxes, which can pose a safety issue. By making the safety of our employees a priority, a better shipping process is guaranteed.

7. Share best practices

Companies should be committed to creating a system that works for all suppliers and collaborate often on what works and what doesn’t. After all, it should benefit everyone to make recyclable shipping materials standard practice and share lessons learned. Developing a set of packaging standards saves time and money, and results in recyclable solutions that reduce waste.

What’s Next?

Reducing waste and disposing of it in an eco-forward manner will help companies economically, both short and long term, and help keep the planet green. Implementing sustainable practices in your facility and encouraging the staff to embrace sustainable habits throughout organizational processes offers tremendous benefits. Promoting sustainability also looks excellent for the brand image, and it’s ownership of corporate responsibility!

How to make your business greener right now?

The simple tips below will help you wisely optimize the website and make your business more attractive to eco-conscious consumers.

• Reduce packaging

From the eco-friendly perspective, the best packaging is no packaging, but it’s hardly possible to refuse wrapping at all. However, as we’ve already mentioned, reduced packaging will significantly decrease your material and logistics costs.

• Use biodegradable materials

Many marketers avoid using compostable packaging because it’s more expensive and looks less appealing to consumers. But all they actually need to do is to find a green material that suits their specific business needs. E.g. Soy-based ink is a sustainable option that offers a rich set of colors that can spice up plain boxes. Plastic packaging is another option that can be recycled or reused.

• Don’t mix items incompatible for recycling

Two or more polymers used together may prevent packaging of recycling the same. Therefore, choose plastic materials for your package stick to one single plastic type.

• Make your package design functional

A food container shaped as a teddy bear or a puzzle box will ensure that packaging gets a second life and won’t end up as wastes.

• Promote your products using long-life items

Select substantial items like pencils, bags, t-shirts, mugs etc. for your marketing campaigns which can be used for a long time and will definitely increase your brand awareness.

• Offer related eco-friendly services

Refilling printer ink or reusing any kinds of package materials will not only cut down on customer spend but it will attract them to you as a green business.

• Instruct customers

Properly mark recycled/recyclable packaging and give proper instructions on their possible reuse or recycling.

• Be reasonable

Don’t make your services or products less quality or convenient just for the sake of looking ecologically conscious.

Green packaging trends

The majority of latest innovations in package design reflect a shift away from the artificial eye-catching packaging that was associated with premium products in the past to natural-looking materials. However, this tendency doesn’t limit manufacturers when it comes to a variety of shapes, surfaces, and package usage scenarios

The future of sustainable packaging will not just be in material usage, light weighting and recycling – but also about empowering consumers with the ability to lead their lives in a more environmentally positive way.

1. Edible packaging

Why throw the package away when you can actually eat it? Following this idea, more and more startups focus on edible food package development to minimize packaging waste. Edible food packaging is basically ‘food wrapped in food’ which is a new trend

2. Tactile or multi-sensory packaging

Tactile packaging has been developed to make products ‘speak’ with the customers. Due to up-to-date advanced technologies tactility can be executed in embossing, raised-letter inks, laser-etching, molded patterns etc. For instance, the package designer Solveiga Pakstaite invented the Bump Mark – which is basically a tactile expiry date. It informs consumers about the state of their food through a simple touch.

3. Multifunctional and zero waste packaging

A new trend gaining popularity over recent years is a package that can be given a new life after its content use.

One of the most classic examples of a multi-functional eco-packaging is a read Puma bag designed by Yves Béhar which only requires fewer production resources but also can be re-used. According to Puma, these bags save about 60 percent of water and energy compared to old-line manufacturing.

References:

https://www.industrialpackaging.com/blog/3-ways-to-reduce-packaging-waste

https://www.3blmedia.com/News/Whole-Package-7-Ways-Companies-Can-Reduce-Packaging-Waste

https://amasty.com/blog/green-packaging-101-make-e-commerce-business-eco-friendly/